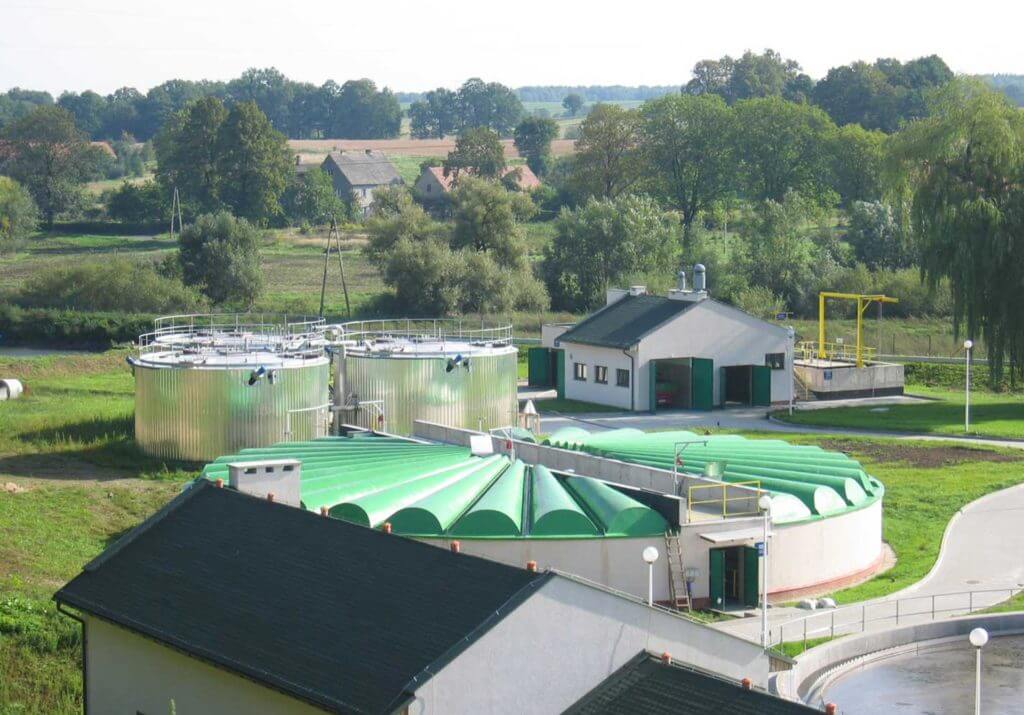

Autoheated Thermophilic Aerobic Digestion ATAD

Stabilized and disinfected sewage sludge as valuable fertilizer

With Autoheated Thermophilic Aerobic Digestion (ATAD) sewage sludge becomes stabilized and disinfected, transforming it into a valuable and cost-effective fertilizer, that fulfills highest international quality requirements (Class A, US EPA 503). Other waste streams that can be treated with the ATAD process include industrial sewage sludge and liquid manure from agriculture.

The aerobic and thermophilic process (temperature range 50-60 °C) facilitates short reaction times, which minimizes the space requirement and therefore the investment costs of sludge treatment. The stable process and robust machine equipment from FUCHS lead to a reliable operation with easy handling.

Through consistent development, the ATAD concept from FUCHS was continuously improved. The combination of increased oxygen introduction at the beginning of the process and the application of newest exhaust air treatment technology made FUCHS ATAD even more effective. The first FUCHS ATAD plant was already built in 1977 and is still in operation. Benefit from our long-standing expertise in the field of aerobic sewage sludge treatment.

Advantages

- Proven technology with more than 30 years of experience

- Simultaneous stabilization and disinfection

- Short process retention times of 7 to 9 days

- Reduced space requirement

- Low investment costs

- High process stability

- Flexible process control

- Easy plant extension

- Plant-compatible fertilizer as end product

- FUCHS ATAD process fulfills international guidelines (e.g. US EPA 503)

- Perfectly suited for industrial and municipal applications